Customer case: SEGRO - DHL Global Forwarding

With the PowerBooster, DHL operates completely independent of the electricity grid

Solar panels, lithium titanium batteries and biodiesel generators provide enough power.

The energy management system PowerBooster dynamically adapts energy sources to changes in energy demand.

Energy availability is guaranteed at 99.9%.

Home " Customer cases " Drive & control technology " SEGRO - DHL Global Forwarding

Mastering grid congestion

DHL Global Forwarding is now running at full power - without a single kilowatt extra from the grid. A powerful answer for companies facing grid congestion, the PowerBooster demonstrates how to achieve complete energy independence with smart technology, renewable resources and thoughtful design.

Challenge

During the construction of DHL's new distribution centre at Schiphol Airport, it turned out that almost no electricity capacity was available from the grid.

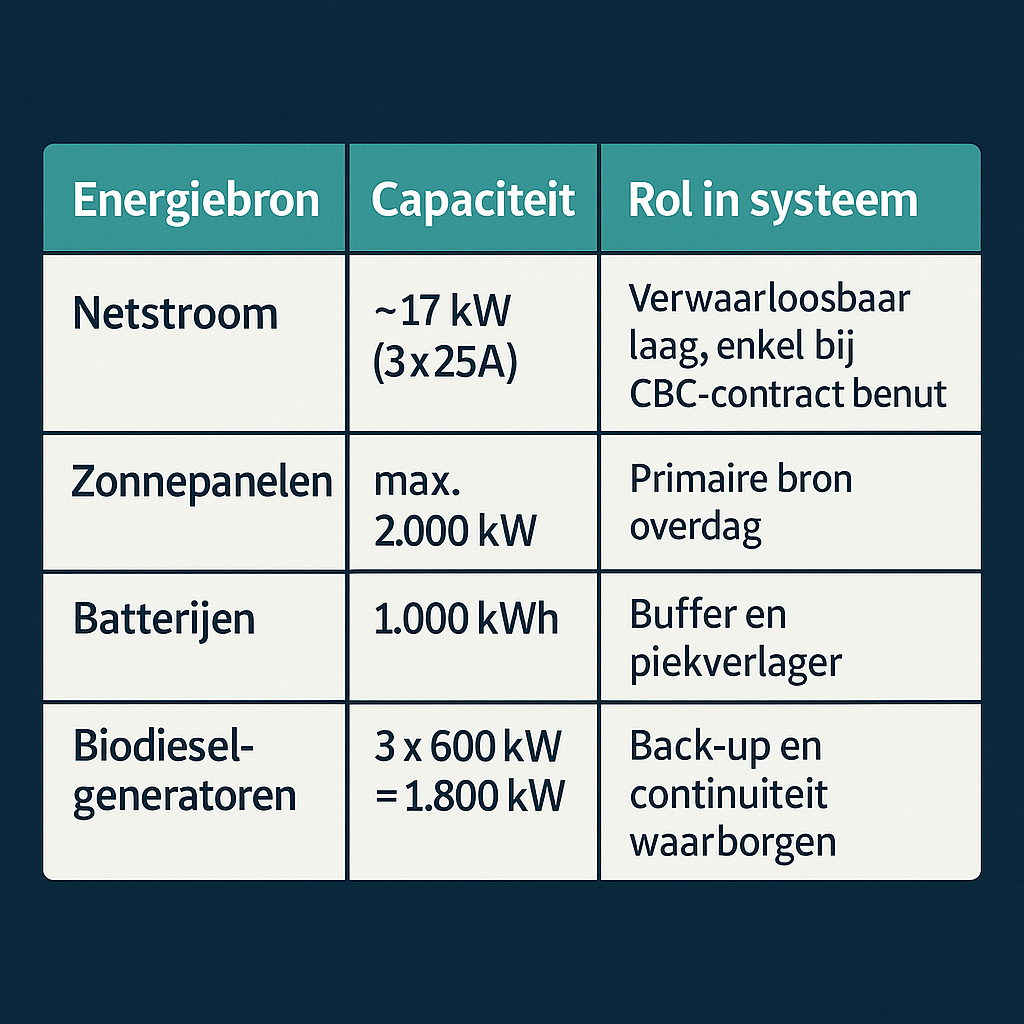

- Available from the grid: only 3 x 25 amps (~17 kW continuous power)

- Capacity required for DHL: up to 2 megawatts (2,000 kW)

In short, due to grid congestion, less than 1% of the distribution centre's total energy requirement was available. An alternative, robust energy solution was required.

"We were connected to the grid, but we were hardly allowed to take anything from it, especially during the day."

- Robbert Hardam, Associate Manager Technical Development at SEGRO

Solution

Problems like grid congestion require innovation and a solution-oriented approach. As sustainable as possible, without compromising on quality and results for the customer.

Real estate developer and lessor SEGRO, DHL Global Forwarding and Electroproject together mapped energy consumption at daily, weekly and seasonal levels. This resulted in the profile on which the energy supply had to be adjusted: high daily peaks, relatively low night load, highly dependent on seasonal influences.

"After calculations, a combination of solar panels, batteries and biodiesel generators proved to be the most sustainable and cost-effective solution."

- Ronald Waaijer, Account Manager at Electroproject

Result

The heart of the solution is the PowerBooster: a smart energy management system that combines three energy sources and continuously adjusts based on availability and demand.

The strength of the system lies in smart switching between sources. The PowerBooster's energy management system (EMS) ensures that solar energy is utilised during the day and potential surpluses are stored in battery storage.

The special lithium titanium batteries are called upon in case of reduced solar radiation or peaks. And as a last resort, 3 biodiesel generators are available.

"We provide a service contract and are on site within four hours if needed."

- Ronald Waaijer, Electroproject

A flexible and safe system

SEGRO wanted to install the batteries indoors, which led to questions around fire safety. Electroproject carefully investigated which battery technology was suitable for this. The chosen lithium titanium solution complies with the PGS-37 standard, which requires, among other things, 24/7 monitoring of the battery status.

A dashboard continuously monitors all energy production, storage and consumption. Any malfunctions are immediately detected and resolved.

Moreover, the PowerBooster is prepared for further energy transitions. Because the system can be used flexibly, SEGRO was still able to conclude an energy contract with dynamic conditions. The PowerBooster adapts in real-time to changes in grid capacity.

"Precisely because we had purchased this smart solution, it was possible to sign such a special energy contract."

- Robbert Hardam, SEGRO

Conclusion

A powerful response to increasing grid congestion, the PowerBooster demonstrates how to achieve complete energy independence with smart technology, renewable resources and thoughtful design. DHL is now running at full power - without a single kilowatt extra from the grid.